XGN66-12 (Z) fixed enclosed switchgear

Overview

Type XGN66-12 fixed closed switchgear (hereinafter referred to as switchgear) is our company’s new generation of high-voltage electrical appliances complete sets of products, in line with the national standard GB3906《3-35kV ac metal closed switchgear “power department DLT404《 indoor ac high-voltage switchgear ordering technical conditions” requirements, but also meet international standards IEC60298《1kV above 52 kV ac metal closed switchgear and control equipment requirements .”

This product absorbs the foreign advanced technology, it is small in size, is only the ordinary switchgear volume 5 The circuit breaker has the advantages of high reliability and good performance. The switchgear is an indoor complete set of 3.6,7.2,12 kV three-phase alternating current 50 Hz single busbar segment, which is used for receiving and distributing electric energy. It also has the functions of controlling, protecting and monitoring the circuit, which can be used in various types of power plants, substations, industrial and mining enterprises, high-rise buildings and other places, and can also be combined with ring network cabinets to be used in the opening and closing places.

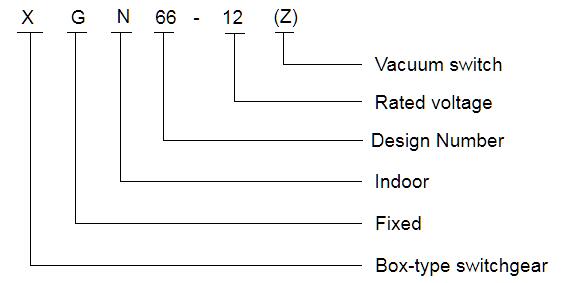

Model meaning

Normal operating conditions

♦ altitude not exceeding 1000 m.

♦ ambient temperature :-25 C 〜+ average temperature not exceeding +35 C 〜+C. within 4 hours

♦ horizontal inclination is not more than 3 degrees.

♦ seismic intensity does not exceed magnitude 8.

♦ no violent vibration and shock and explosion hazard sites.

Structural characteristics

♦ The cabinet is welded with high-quality angle steel.

♦ The circuit breaker room is located in the middle (lower) part of the cabinet, which is convenient for installation, debugging and maintenance. Equipped with VS1 circuit breaker as standard and equipped with pressure release channel to ensure personal safety.

♦ Adopting advanced and reliable rotary isolating switch, it can safely enter the circuit breaker room for maintenance when the main bus is live.

♦ Enclosure protection grade IP2Xo

♦ It is equipped with a compulsory mechanical locking device with reliable functions, which can meet the requirements of “five preventions” simply and effectively.

♦ Has a reliable grounding system.

♦ The door is equipped with an observation window, which can clearly observe the working state of the components in the cabinet.

♦ The operating mechanism is locked with the same JSXGN locking mechanism as XGN2-12 cabinet, which is simple, reliable, convenient and practical.

♦ Inlet and outlet cables are lower than the front of the cabinet, which is convenient for users to connect

Main technical parameters of vacuum circuit breaker

| Main technical parameters and components of switchgear | |||

| Serial number | Projects | Unit | Technical parameters |

| 1 | Rated voltage | kV | 3.6,7.2,12 |

| 2 | Rated power frequency withstand voltage | kV | To the ground, interphase :42: fracture :48 |

| 3 | Rated lightning impulse withstand voltage | kV | To the ground, interphase :75: fracture :85 |

| 4 | Rated frequency | Hz | 50 |

| 5 | Rated current | A | 630,1250, |

| 6 | Rated short-circuit breaking current (effective) | kA | 20,25,31.5, |

| 7 | Rated short-circuit closing current (peak) | kA | 50,63,80, |

| 8 | Rated dynamic steady current (peak) | kA | 50,63,80 |

| 9 | 4 s (Valid) Rated Thermal Stability Current | kA | 20,25,31.5 |

| 10 | Protection level | IP2X | |

| 11 | Shape dimensions (width x depth X height) | mm | 900x1000x2300 |

| 12 | Weight | kg | ≈ 600 |

Main Technical Parameters of QCE1-12 Type Vacuum Circuit Breaker

| Serial number | Projects | Unit | Technical parameters |

| 1 | Rated voltage | kV | 12 |

| 2 | Rated current | A | 630 1250 |

| 3 | Rated short circuit switching current | kA | 20,25,31.5 |

| 4 | Rated short-circuit closing current | kA | 50,63,80 |

| 5 | rated short-time withstand current (4 s effective) | kA | 20,25,31.5 |

| 6 | Rated peak tolerance current (peak) | kA | 50,63,80 |

| 7 | Mechanical life | Third | 10000 |

| 8 | Rated short-circuit breaking current breaking | Third | 50 |

| 9 | I page of Rated Operations | s–0.3 and 180 | |

| 10 | Contact opening | mm | 11±1 |

| 11 | Contact stroke | mm | 4±0.5 |

| 12 | Interphase central distance | mm | 210 |

| 13 | Opening speed | m/s | 1.2±0.2 |

| 14 | Closing speed | m/s | 0.6±0.2 |

| 15 | Opening Time | ms | ≤60 |

| 16 | Closing Time | ms | ≤ 75 |

| 17 | Simultaneous Phase of Three-phase Switching | ms | ≤ 2 |

| 18 | Bounce on closing | ms | ≤ 2 |

| 19 | Circuit resistance | ≤ 45 | |

| 20 | Cumulative allowable wear thickness of contacts | mm | 3 |

◊ the technical parameters of other electrical components see their respective instructions.

◊The scheme of ◊ switchgear rated current greater than 1600 A shall be settled in consultation with our company.

Installation

♦ installation foundation refer to the following figure, the foundation channel steel protruding ground 1-3 mm, within a meter range of unevenness should not exceed 1.5 mm, within the full length range of not more than 5 mm..

♦ place the switchgear on the basis of sequence, adjust the position of installation. Then use M12 bolts or spot welding method to fix, cabinet and cabinet with M8 bolts and tight. After ♦ disassembly, the cover plate is installed with main bus and primary cable, and the terminal contact surface should be cleaned and coated with neutral vaseline. Plug the cable hole once after installation.

♦ connection cabinet indirect ground bus, so that along the direction of the switchgear arrangement into one, check whether there are omissions in working grounding and protection grounding, grounding circuit is continuous conduction, working grounding resistance should not be more than 1000 m Q, protection grounding resistance should not be more than 4 Q..

♦ install the secondary cable, the cable is introduced by the front bottom of the cabinet, and the side wall enters the low voltage chamber, which is connected to the terminal row separately; or the low voltage chamber is introduced from the secondary small busbar on the top of the cabinet, and the cable hole is plugged after installation.

♦ clean up the dust and debris in the cabinet.

Operation

♦ Before the ◊ is put into operation, the following inspection and commissioning shall be carried out:

♦ check whether the type and specification of the electrical components installed in the cabinet are in accordance with the order requirements; check whether the fasteners are loose; check whether the first or second wiring is correct; operate the isolating switch, grounding switch, circuit breaker, mechanical interlock 3~5 times, should be flexible jam phenomenon, interlock meet the “five prevention” requirements, and then add grease to the mechanical active parts.

♦ check the insulation level of switchgear and circuit resistance, mechanical characteristics of circuit breaker according to article 3 of this specification and factory test report, the test results should be consistent with or similar to the factory test report.

Maintenance and repair

♦ users should maintain and overhaul the switchgear regularly.

◊ cleaning of all parts of dust, especially the surface of insulation dust;

◊ check the moving parts of machinery, add grease regularly to keep it flexible and reliable.

◊ circuit breaker, isolation switch, grounding switch and other components maintenance according to their respective instructions;

◊ check whether the electrical contact part is good, whether there is overheating phenomenon, grounding circuit is on;

◊ check regularly whether the fasteners are fastened.

♦ the user should generally with the assistance of the manufacturer to carry out troubleshooting, in case of minor adjustments and minor failures, the user’s self-repair should refer to this specification and the main components of the respective specifications.

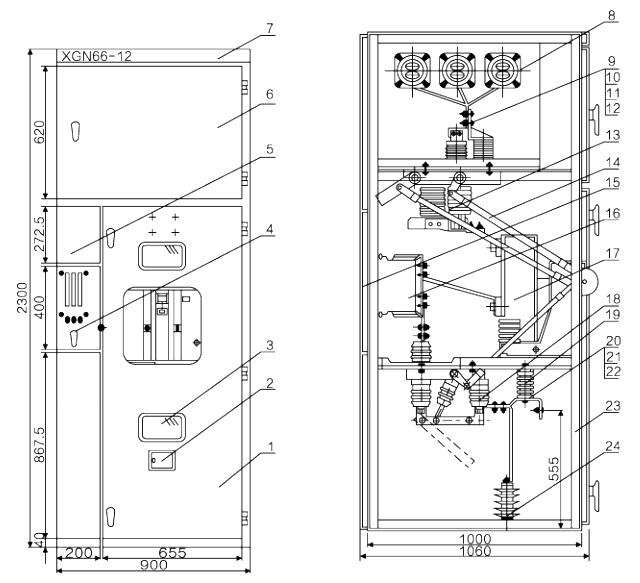

Schematic diagram of switchgear layout