XGN-12 intelligent solid insulation cabinet

Overview

XGN-12 series solid fully insulated closed ring network switchgear is a fully insulated, fully sealed, maintenance-free solid insulation vacuum switchgear. all the high voltage live parts are poured and formed with epoxy resin material with excellent insulation performance. the vacuum arc extinguishing chamber, leading electrical circuit, insulation support and so on are organically combined into a whole, and the functional units are connected by a fully insulated solid busbar. Therefore, the whole switchgear is not affected by the external environment, which can ensure the reliability of the operation of the equipment and the safety of the operator.

Having the characteristics of simple structure, flexible operation, reliable interlocking and convenient installation, the ring net cabinet is suitable for 50 kV power system. It is widely used in industrial and civil cable ring network and distribution network terminal project. It is especially suitable for distribution, small substation, opening and closing station, cable branch box, box substation, industrial and mining enterprises, shopping mall, airport, subway, wind power, hospital, stadium, railway, tunnel and so on.

Because the product has the advantages of full insulation, full sealing and full shielding, it is especially suitable for use in areas with high altitude, high temperature, damp and heat, cold, serious pollution and other harsh environment.

Product classification

The switch is divided into load switch with earthing assembly (C module), load switch without earthing assembly (CB module), circuit breaker with earthing assembly (short V module), circuit breaker without earthing assembly (short VB module), circuit breaker contact switch (short VZ module), load switch + fuse combination electrical switch assembly (short F module), isolating switch assembly (short).

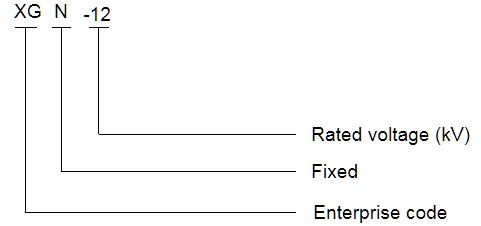

Model meaning

Conditions of use

♦ Ambient temperature: -45℃ ~+45℃

♦ Humidity: maximum average relative humidity, daily average ≤ 95%, monthly average ≤ 90%

♦ Altitude: ≤ 2000 meters

♦ Earthquake resistance: 8 degrees

♦ Protection level: charged body seal IP67, fuse tube lP67, switch cabinet shell IP3X

Functions and Features

Environmental protection:

The materials used in product manufacturing are all non-toxic and non-hazardous substances, and no toxic and hazardous substances will be discharged during use. The materials can be recycled after the life cycle, which determines the environmental protection of the use.

Fully-insulated, fully-sealed, and fully-shielded epoxy resin switch simplified, fuse simplified (epoxy resin has excellent electrical properties, mechanical properties, thermal characteristics, used early in electrical equipment, and achieved good results. Switch simplified, fuse Simplified by the epoxy resin APG process. Insulated Simplified is the key component of the solid insulated switch, it is both an insulating part and a bearing part. It is required to meet the technical requirements of heat resistance, weather resistance, crack resistance, high mechanical strength, good insulation strength, etc. .Simplified volume is large, there are many inserts, different shapes, and manufacturing is difficult. Our company has many years of experience in designing and manufacturing insulating parts. From the barrel design, material formula, and process flow, we have worked hard to ensure the quality of the parts Production. According to user requirements, can provide the outer shield grounding can touch the barrel)

Maintenance free:

Except for the operating mechanism, the high-voltage switch part of the solid insulated indoor AC high-voltage vacuum switchgear is fully sealed, so that it can be free from cleaning and maintenance, and reduces the cost of operation and maintenance.

safety:

Since the touchable part adopts shielding measures, it can prevent the occurrence of personal electric shock accidents and improve the safety of use. Perfect interlocking interlocking system, three-phase isolation fractures are clearly visible, avoiding misoperation accidents. The application of SF6 gas was completely cancelled, and the explosion accident caused by the decrease in insulation performance and arc extinguishing ability caused by insufficient gas pressure in the SF6 ring network cabinet was avoided. Strengthen the phase-to-phase isolation structure to avoid phase-to-phase or multi-circuit short circuiting to expand or cause an explosion accident. A vacuum arc extinguishing chamber with explosion-proof performance is adopted, and the switch sleeve has further protection performance for the switch. Load switch-The auxiliary earthing switch of the fuse combination electric appliance is fixed in the fuse barrel by vacuum switch tube.

Easy to operate:

The isolation switch grounding switch has only one operating handle, no need to identify and worry about mistakes, when the circuit breaker is running, the operating handle of the isolation switch grounding switch can not be operated, the operation procedure is clear, as long as a person with a little knowledge of electrician will operate, and it will be carried out in disorder Complex technical training. This makes the operation extremely simple and prevents operation errors.

Intelligent:

The switchgear is left with an intelligent interface and sensor installation location, and after configuring intelligent equipment, it can meet the requirements of the smart grid.

Various operating mechanisms:

The switch can be equipped with two operating mechanisms, spring and permanent magnet, which are convenient for users to choose.

Compliance criteria

♦ Q/GDW 730-2012 “Technical conditions of 12kV solid insulated ring network cabinet”

♦ GB1984 “AC High Voltage Circuit Breaker”

♦ GB3804 3.6kV-40kV “AC high voltage load switch”

♦ GB1958 “AC high voltage isolating switch and grounding switch”

♦ GB4208 “Enclosure Protection Grade IP Code”

♦ GB 16926 high-voltage AC load switch-fuse combination appliance

♦ GB/T15166.2 High-voltage AC fuse group Part 2: Current-limiting fuse

♦ GB/T7354 “Partial Discharge Measurement”

♦ GB/T11022 “Common technical conditions for high-voltage switchgear and control equipment standards”

♦ GB3906 “3.6-40.5kV AC metal enclosed switchgear and control equipment”

The main technical parameters

| project | Single place | parameter | project | Single place | parameter |

| conventional | Rated short-circuit making current | kA | 50(63) | ||

| Rated voltage | kV | 12 | Rated short-time withstand current | kA/S | 20/4(25/4) |

| Rated frequency | Hz | 50 | Circuit breaker mechanical life | Next | 20000 |

| Power frequency withstand voltage | kV/min | 42/48 | Circuit breaker electrical life | Next | E2 |

| Lightning impulse voltage | kV | 75/85 | Rated operating sequence | O-0.3s-CO-180s-CO | |

| Arc duration | s | ≥0.5 | Partial Discharge | PC | ≤5 |

| -Protection level of secondary parts (except measuring cabinet) | IP67 | Load switch_ | |||

| Cabinet protection level | IP4X | Fuse combination electrical unit | |||

| Compartment protection level | IP2X | Rated current (maximum) | A | 200 | |

| Operating power supply voltage | V | DC24, 48, 110, 220 | Rated short-circuit breaking current | kA | 31.5 |

| AC110, 220 | Rated short-circuit making current | kA | 80 | ||

| Busbar system | Partial Discharge | PC | 3150 | ||

| Rated current | A | 630(1250) | Isolating switch | ||

| Rated short-time withstand current | kA/s | 20/4(25/4) | Rated current | A | 630/1250 |

| Rated peak withstand current | kA | 50(63) | Rated short-time withstand current | kA | 20/25 |

| Rated peak withstand current | kA | 50 | Rated short duration | s | 4 |

| Load switch unit | Rated peak withstand current | kA | 50/63 | ||

| Rated current | A | 630 | Mechanical life | Next | 3000 |

| Rated short-circuit making current | kA | 50 | Earthing switch | ||

| Rated short-time withstand current | kA/s | April 20 | Rated current | A | 630/1250 |

| Mechanical life of load switch | Next | Rated short-time withstand current | k | 20/25 | |

| Electrical life of load switch | Next | E3 | Rated short duration | S | 4 |

| Partial Discharge | PC | ≤5 | Rated peak withstand current | k | 50/63 |

| Circuit breaker unit | Rated short-circuit making current (peak value) | kA | 50 | ||

| Rated current | A | 630(1250) | Rated short-circuit making current | Next | 2 |

| Rated short-circuit breaking current | kA | 20(25) | Mechanical life | Next | 3000 |

It can be equipped with spring, permanent magnet two operating mechanism, easy for users to choose.

Application areas

♦ Low temperature and cold area: no SF6 gas application, no need to consider the problem of low temperature operation of SF6 gas, it can also operate normally at -45℃.

♦ Plateau area: No need to consider the influence of plateau atmospheric pressure on insulation performance.

♦ Strong wind and sand area: The safety protection grade of the solid insulated ring network cabinet body is IP67, and the control circuit room adopts special treatment to ensure long-term operation in the strong wind and sand area.

♦ Coastal wet pool area: epoxy resin sealed, resistant to humidity and salt spray corrosion, to ensure long-term use in coastal areas.

♦ Areas with high environmental protection requirements: The impact of SF6 gas on atmospheric warming has been highly valued. The solid ring network cabinet has canceled SF6 gas, without any pollution and harm to the environment and people.

♦ In the smart grid: since the main switch and the isolating switch can be electrically operated, the intelligent controller developed by our company can be selected to remotely control, remotely measure, and remotely switch equipment and substations.

Telecommunications can not only perform decentralized control, but also facilitate centralized control.

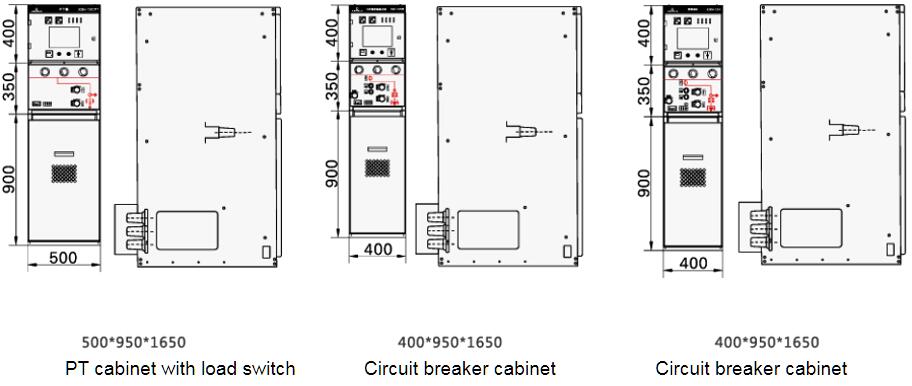

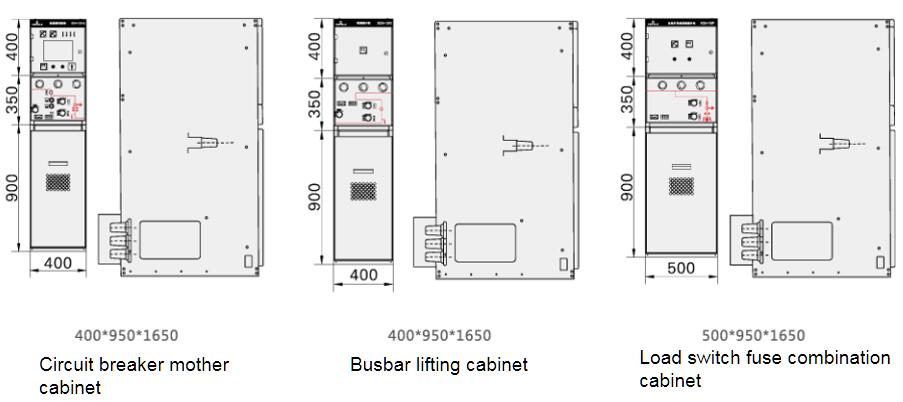

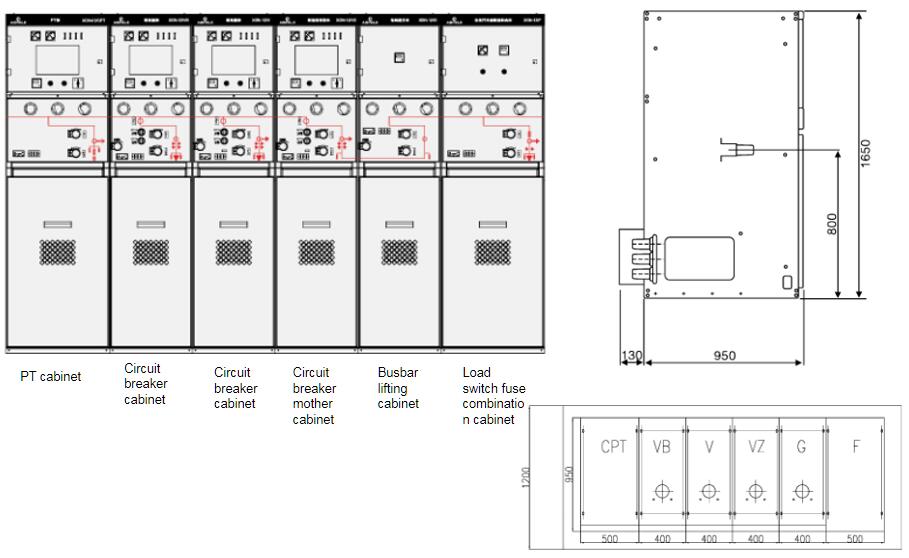

Dimensions

Note:

1. concrete cushion bottom should be rammed with plain soil;

2. the total length of the switchgear does not exceed 2 meters may not add the pillar, but when the total length of the switchgear exceeds 2 meters, every 2 meters span needs to add one pillar;

3. the 2600 space behind the cabinet is the pressure relief channel of the switchgear, so a group of switchgear, the two ends of the cabinet need to add protective fence;

4. figure H according to the maximum cable bending radius.

Transport and storage

♦ packaged ring net unit can be carried by electric forklift or crane, and the ring net unit is equipped with a hoisting ring for hoisting when handling. A rope should not be less than 2 m. for lifting

♦ ring net unit should be placed in a dry, ventilated, dust-free place before installation in use site. If covered with plastic bags, the bottom should be ventilated open

Use and maintenance

a. Inspection before use: Before using the ring network unit, for personal and equipment safety, the following inspections must be carried out

♦ Check whether the main circuit and the ground circuit are properly connected.

♦ Check whether the mechanical interlock is correct and reliable.

♦ Check whether the operation of the load switch and grounding switch in the ring network unit is flexible and correct.

♦ Check whether the connection of high-voltage cable is correct and reliable.

b. Run

♦ The ring network unit should be put into operation according to the prescribed operation sequence.

c. Maintenance: This equipment is based on the following advantages and does not require routine maintenance

♦ All live parts are installed in epoxy plastic grease insulation cylinder.

♦ All the operating mechanism parts placed outside the epoxy resin grease insulation cylinder have been plated.

♦ The main shaft is supported by a copper bushing, that is, it can work continuously and effectively without adding lubricant.

Note: If the ring network unit is faulty, do not try to open the ring network unit for repair with a drilling machine, cutting machine or other tools. These operations can only be carried out by the personnel of our company.

Randomized documents and annexes

When the product leaves the factory, the following materials and accessories are provided randomly:

♦ Product installation manual

♦ Product factory test report

♦ Product Qualification Certificate

♦ Packing list

♦ Operating handle

♦ Other accessories